Thermal Stability of WTB Wire to Board Connectors in High-Temperature Environments

Material Considerations for Heat Resistance

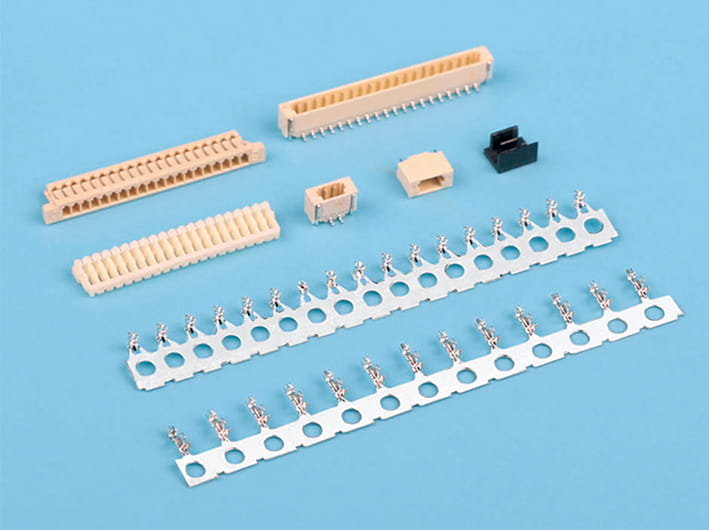

The performance of any electronic connector in elevated temperature environments depends significantly on the materials used in its construction. A WTB Wire to Board Connector typically comprises metal terminals and a plastic or thermoplastic housing. In high-temperature conditions, the thermal stability of these materials becomes critical. Reputable manufacturers use high-temperature plastics like LCP (Liquid Crystal Polymer) or PA46, which can withstand temperatures up to 260°C without warping, degrading, or losing mechanical integrity. Meanwhile, the metal components—usually copper alloy with tin or gold plating—must retain their conductivity and mechanical properties under thermal stress to ensure signal reliability and contact retention.

Mechanical Performance at Elevated Temperatures

Heat exposure can cause thermal expansion, which may affect the connector’s structural fit between the wire and board interface. An effective WTB Wire to Board Connector is designed to accommodate these expansions with tolerance-controlled housings and terminal designs. Spring-force contacts or dual-beam terminals are often used to maintain consistent contact pressure even as components expand or contract. This is especially crucial in applications like engine control units, industrial motor drives, or outdoor communication equipment, where temperatures can exceed 100°C during operation.

Impact on Electrical Properties

Temperature can directly influence the electrical resistance and insulation properties of connectors. A well-designed WTB Wire to Board Connector will maintain a low contact resistance and high dielectric strength even when exposed to long-term heat. Excessive heat can degrade insulation materials and cause tracking or short circuits. Therefore, connectors used in thermally demanding environments often include flame-retardant materials and follow standards like UL94 V-0 to ensure fire resistance and continued electrical performance.

Long-Term Reliability and Aging

Thermal aging is another concern when evaluating connectors for high-temperature use. Prolonged exposure to heat can cause oxidation, especially in non-precious metal finishes like tin. This can degrade the contact surface, causing increased resistance and potential connection failure. High-performance WTB Wire to Board Connectors designed for thermal durability may use gold plating for critical signal paths, which offers good corrosion resistance and longevity in hot environments. Additionally, connectors rated for high Mean Time Between Failures (MTBF) are more suitable for applications with consistent thermal stress.

Connector Ratings and Testing Standards

Industry standards such as IEC 60512 and UL 1977 provide testing frameworks to evaluate the heat resistance and current-carrying capacity of connectors under thermal load. A dependable WTB Wire to Board Connector should carry certifications or test data proving its capability to operate safely in specified thermal ranges. Typical automotive-grade connectors are tested to function in -40°C to +125°C environments, while some industrial models are designed for even higher ranges.

Application-Specific Design Enhancements

In addition to materials and mechanical design, some connectors are equipped with thermal protection features such as heat shields, ventilation-friendly layouts, or enhanced creepage and clearance distances to prevent dielectric failure. For applications where continuous exposure to heat is expected, designers should select connectors with proven high-temperature ratings and consider system-level heat management like spacing, airflow, and PCB design.

Selecting the Right Connector for the Right Conditions

The thermal stability of a WTB Wire to Board Connector is not just a matter of surviving high temperatures—it’s about maintaining long-term electrical, mechanical, and safety performance under challenging conditions. By understanding the material properties, mechanical resilience, and compliance with international testing standards, engineers can confidently select connectors that will perform reliably in high-heat environments. Proper connector selection ensures system integrity, reduces maintenance needs, and enhances overall product longevity.

English

English 中文简体

中文简体 Español

Español عربى

عربى