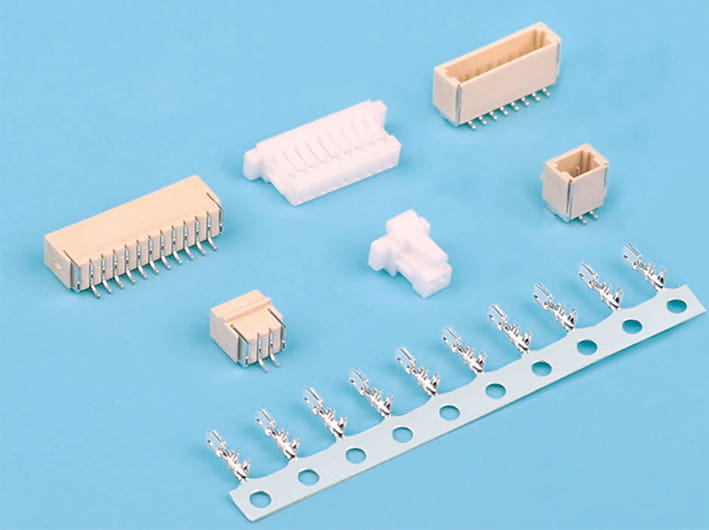

Performance Assessment of WTB Wire to Board Connectors Under Vibration Conditions

Challenges of Vibration on Electrical Connections

In automotive, aerospace, and industrial environments, electrical systems are often subjected to continuous or intermittent vibration. These conditions pose a serious challenge to connector performance, particularly for signal and power connections that demand consistent conductivity. A WTB Wire to Board Connector, bridging discrete wires to PCB-mounted interfaces, must resist loosening, fretting corrosion, and intermittent contacts caused by vibration-induced movement. Poor connector performance under such stress can result in data errors, power disruption, or total device failure.

Structural Design for Vibration Resistance

One of the key factors in a connector's vibration performance is its mechanical structure. High-quality WTB Wire to Board Connectors are engineered with robust locking mechanisms, such as positive latches or locking tabs, that secure the housing to the header, preventing unintentional disengagement. Additionally, many designs incorporate dual-beam or box-type contact terminals that maintain strong contact force, ensuring the wire and board interface remains tight even during continuous shaking or shock. These features help maintain stability while reducing micro-movement that can degrade metal surfaces over time.

Terminal Retention and Contact Reliability

The terminal design directly impacts a connector’s ability to perform under vibration. Spring-loaded terminals or multiple contact points are preferred in high-vibration conditions because they provide redundancy in electrical pathways. As vibration can cause micro-gaps or momentary separation between contacts, these advanced terminal structures help ensure that current flow remains uninterrupted. Plating materials, such as gold over nickel, are often used to prevent fretting corrosion and maintain low contact resistance throughout the product lifecycle.

Materials and Tolerances Matter

The material selection for both housing and terminals contributes to vibration resilience. High-performance thermoplastics such as PBT or LCP are commonly used for housings due to their dimensional stability and resistance to cracking under stress. Precision molding ensures that each terminal is tightly held in place, reducing internal movement that could contribute to wear. Furthermore, low insertion force designs help ensure that connectors can be mated securely without damaging components, yet still provide strong retention during vibration exposure.

Testing and Certification for Vibration Performance

Many manufacturers subject their WTB Wire to Board Connectors to standardized vibration tests by international benchmarks such as IEC 60512-6-4 or EIA-364-28. These tests simulate various vibration profiles over extended durations to measure electrical continuity, insertion force retention, and contact resistance shifts. Test results provide confidence in real-world applications, particularly when connectors are destined for use in automotive control systems, engine compartments, or factory robotics, where vibration is constant and unavoidable.

Design Practices for Vibration-Sensitive Applications

To ensure reliable performance in a vibrating environment, proper connector choice must be paired with sound PCB and wiring design. Support structures such as strain reliefs, cable tie-downs, or vibration-damping mounting surfaces can greatly reduce the mechanical load on the connector itself. Avoiding long unsupported wire lengths, routing wires to reduce tugging, and selecting right-angle headers when appropriate can also contribute to enhanced system durability.

Engineering Confidence Through Vibration-Tolerant Connector Solutions

The ability of a WTB Wire to Board Connector to perform in vibration-heavy environments is determined by a combination of mechanical security, material quality, and electrical contact design. With proper design features such as locking mechanisms, multi-point terminals, and vibration testing compliance, these connectors can deliver reliable performance even in demanding settings. Selecting connectors optimized for vibration resistance ensures system integrity, reduces downtime, and supports the longevity of critical electronic applications.

English

English 中文简体

中文简体 Español

Español عربى

عربى