Maintaining Signal Integrity in High-Speed Board to Board Connector Applications

Introduction to High-Speed Signal Challenges

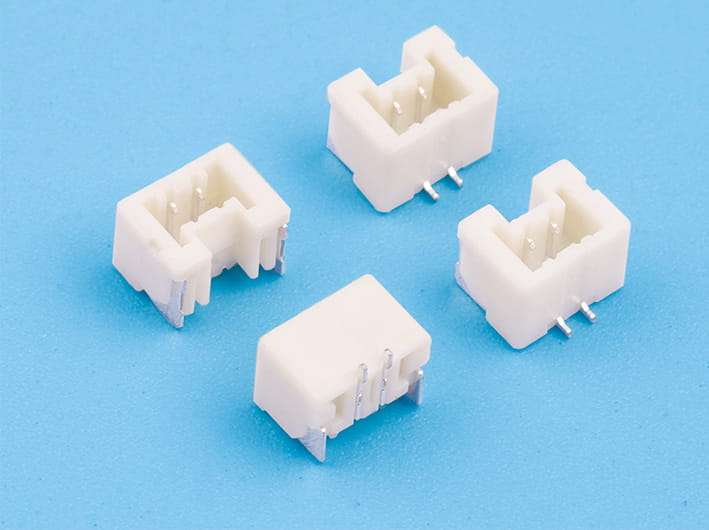

In modern electronics, high-speed data transmission has become increasingly critical across computing, telecommunications, and industrial applications. A Board to Board Connector is often a central component in multi-layer PCB systems, linking two circuit boards while allowing electrical signals to pass efficiently. Maintaining signal integrity at high frequencies is a significant challenge because connectors can introduce reflections, crosstalk, and insertion loss. Understanding the principles that influence signal quality, as well as the engineering strategies to mitigate degradation, is essential for reliable and high-performance designs.

Signal Reflection and Impedance Matching

One of the primary factors affecting high-speed signal integrity is impedance mismatch. Every connector introduces a transition in the transmission path that can reflect energy toward the source, causing distortion and potential data errors. Board-to-board connectors are designed with controlled impedance profiles, often matching the characteristic impedance of the PCB traces, typically 50 or 100 ohms. Manufacturers achieve this through precise pin spacing, contact geometry, and careful arrangement of signal and ground terminals. Proper impedance matching reduces reflections and ensures that high-frequency signals propagate without distortion, which is essential for applications such as PCIe, USB 3.0, or high-speed memory interfaces.

Crosstalk Mitigation Techniques

Another challenge in high-speed transmission is crosstalk, where signals on adjacent pins or traces induce unwanted interference. Board to Board Connectors often include design features to reduce crosstalk, such as differential pair routing, signal pin isolation, and grounded shielding between high-speed channels. Differential signaling is particularly effective because it transmits data as a voltage difference between two complementary lines, which reduces susceptibility to external noise. By controlling the physical layout of the connector and the surrounding PCB, engineers can maintain signal clarity even in densely packed, high-frequency environments.

Reducing Insertion Loss and Signal Attenuation

Insertion loss, which refers to the loss of signal power as it passes through the connector, is another key consideration. Low-resistance contacts and high-quality conductive materials, often plated with gold or other corrosion-resistant metals, reduce resistive losses. Additionally, short and optimized signal paths within the connector decrease parasitic capacitance and inductance that contribute to signal attenuation. Selecting a connector with the correct pitch, contact geometry, and material composition is crucial for preserving signal amplitude and timing integrity.

Mechanical and Environmental Considerations

Mechanical precision and environmental stability also play significant roles in signal performance. Variations in contact alignment, board spacing, or connector compression can alter impedance and introduce additional reflections. High-quality Board to Board Connectors are designed with tight mechanical tolerances to maintain consistent electrical performance under vibration, thermal cycling, and mechanical stress. Environmental protections such as anti-oxidation coatings, controlled insertion force, and reinforced housings help ensure long-term reliability, preserving signal integrity throughout the product lifecycle.

Ensuring signal integrity in high-speed applications using Board to Board Connectors requires a combination of electrical, mechanical, and material considerations. Impedance matching, crosstalk mitigation, and insertion loss are key electrical strategies. At the same time, precise manufacturing, robust mechanical design, and environmental protection support consistent performance over time. By carefully selecting and implementing high-quality connectors, engineers can achieve reliable, high-speed data transmission without compromising system efficiency or reliability. The result is a robust interconnection solution capable of supporting modern electronic demands in a wide range of applications.

English

English 中文简体

中文简体 Español

Español عربى

عربى