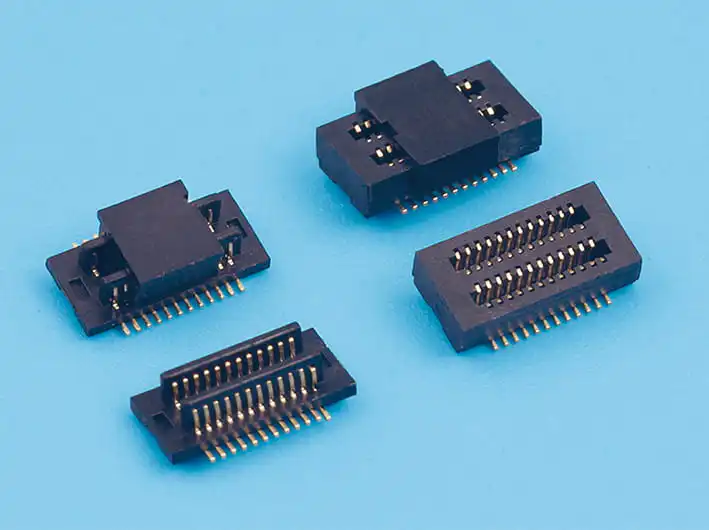

Compatibility of Board to Board Connector with Various PCB Thicknesses

In electronic design, printed circuit boards (PCBs) vary widely in thickness and copper layer specifications. Designers often face the challenge of connecting boards with differing physical and electrical properties without compromising signal quality or mechanical stability. A Board to Board Connector must accommodate these variations to ensure reliable electrical contact and robust mechanical performance. Compatibility with multiple board thicknesses and copper layer gauges is a critical consideration for multi-layer assemblies, stacked modules, and compact electronic devices where space constraints and performance requirements intersect.

Mechanical Accommodation for Different Board Thicknesses

The mechanical design of the connector largely determines its ability to handle PCBs of varying thickness. High-quality connectors feature adjustable or flexible contact pins that can accommodate slight differences in board height without losing contact integrity. Stacked board designs often require connectors with specific mating heights, ranging from a few millimeters to several centimeters, while maintaining secure alignment. Some connectors offer multiple versions optimized for specific thickness ranges, allowing designers to select the fit based on board configuration. Additionally, the housing and retention features of the connector help maintain consistent compression force across boards of different thicknesses, preventing loose connections or mechanical fatigue during assembly and operation.

Electrical Considerations for Copper Layer Variations

Copper thickness, measured in ounces per square foot, affects both signal transmission and thermal performance. A connector must ensure consistent electrical contact regardless of variations in PCB copper layers. Thicker copper traces may require slightly higher insertion force to achieve reliable electrical contact, while thinner copper may be more prone to damage if the connector pins exert excessive pressure. Manufacturers often design contact terminals with suitable compliance to accommodate these variations, using spring-loaded or cantilevered pins that can adjust to different surface thicknesses while maintaining low resistance connections. This design approach reduces the risk of signal degradation and ensures long-term reliability even in boards with heterogeneous copper layer configurations.

Connector Design Strategies for Versatility

To support a wide range of board and copper thicknesses, many modern Board to Board Connectors employ modular designs or offer multiple pin length options. Modular connectors allow for stacking different board layers while preserving signal integrity, and extended pin lengths can accommodate thicker PCBs without losing mechanical stability. Some designs also incorporate dual-spring or dual-contact technology to adapt to boards of varying thickness while maintaining secure electrical contact. By selecting a connector with flexible mechanical and electrical characteristics, engineers can design multi-board systems without being constrained by rigid specifications.

Practical Guidelines for Ensuring Compatibility

When implementing a connector across boards of varying thickness and copper layers, careful planning is essential. Designers should measure actual board dimensions, verify copper layer weights, and choose connectors with compliance ranges suitable for those specifications. It is also recommended to test prototypes under operating conditions, including thermal cycling, vibration, and repeated insertion/removal, to confirm mechanical and electrical stability. Ensuring proper soldering or press-fit installation, along with adherence to manufacturer guidelines, improves performance and reduces the risk of premature failure.

A well-designed Board to Board Connector can support a wide range of PCB thicknesses and copper layer variations without compromising mechanical or electrical performance. Through flexible pin design, compliant terminals, and modular or adjustable housing structures, these connectors provide the versatility needed for modern multi-board assemblies. By carefully selecting and implementing the right connector, designers can achieve reliable interconnections across diverse PCB configurations, ensuring signal integrity, mechanical robustness, and long-term durability in electronic systems.

English

English 中文简体

中文简体 Español

Español عربى

عربى