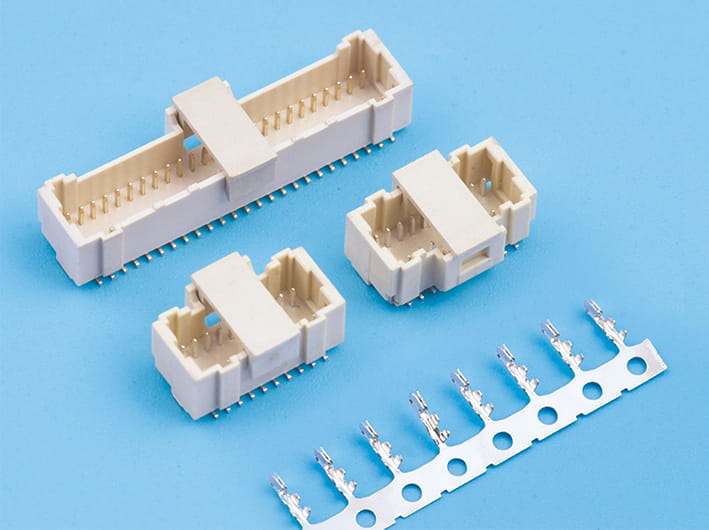

Water and Dust Resistance Features of WTB Wire to Board Connector Designs

In modern electronics, devices are increasingly exposed to challenging environments, including moisture, dust, and airborne contaminants. For a WTB Wire to Board Connector, environmental protection is a critical design consideration. Connectors that lack proper sealing can experience corrosion, short circuits, and reduced lifespan, which compromises device reliability. Designers often prioritize connectors with water- and dust-resistant features for applications such as automotive systems, industrial machinery, outdoor equipment, and consumer electronics. Understanding how these connectors achieve protection and how effective these features are under real-world conditions is essential for ensuring long-term performance.

Sealing Mechanisms for Water Resistance

Waterproofing in wire-to-board connectors is typically achieved through the integration of gaskets, O-rings, and molded seals. These components prevent liquid ingress at key interface points, including the terminal-to-housing connection and the mating area with the PCB. Many connectors are rated according to the IP (Ingress Protection) standard, with common ratings such as IP67 indicating full dust protection and immersion capability in water up to one meter. By creating a tight seal around the terminals and housing, these connectors decrease the risk of electrical shorts, corrosion, or performance degradation caused by water exposure. High-quality materials, such as silicone or EPDM rubber, are often used for gaskets to maintain flexibility and durability under thermal and mechanical stress.

Dust Protection Strategies

Dust protection is equally important, especially in environments like industrial manufacturing floors or outdoor installations, where airborne particles can accumulate inside connector housings. A WTB Wire to Board Connector achieves dust resistance through precise tolerances in the housing design, specialized terminal positioning, and tight mating interfaces. Dust ingress can cause intermittent electrical contact, increased resistance, and even permanent damage over time. High-end connectors incorporate layered barriers or multi-stage sealing designs that reduce particle penetration without compromising mechanical or electrical performance. By maintaining clean contact surfaces, these connectors provide stable signal transmission and reduce maintenance needs in harsh conditions.

Material Considerations and Durability

The effectiveness of water and dust resistance also depends on material selection. The housing and insulation materials must withstand chemical exposure, UV radiation, and temperature extremes while retaining elasticity for seal performance. Metal contacts are often plated with corrosion-resistant finishes, such as gold or tin, to maintain conductivity even if minor moisture or contaminants reach the terminal area. Furthermore, the connector design must account for repeated insertion and removal cycles, ensuring that seals remain effective over time. Properly designed and manufactured WTB Wire to Board Connectors balance durability, protection, and ease of use.

Practical Applications and Testing

In practical terms, these connectors are tested under standardized conditions to verify performance. IP-rated immersion, dust chamber exposure, and thermal cycling are common evaluation methods. Designers must consider the intended operating environment when selecting a connector, ensuring that its protective features match application requirements. For example, automotive engine compartments require high-temperature, vibration-resistant, and dust-tight connectors, while outdoor LED lighting systems may require full water immersion resistance. Installation and maintenance practices also affect performance; correct mating, seal placement, and periodic inspection are essential to retain protection over the device lifecycle.

Overall, a well-engineered WTB Wire to Board Connector can provide reliable protection against water and dust ingress. Through careful design of sealing mechanisms, high-quality materials, and precise manufacturing, these connectors maintain stable electrical performance even in demanding environments. By selecting the right connector and adhering to proper installation practices, engineers ensure both safety and longevity, making wire-to-board systems suitable for a wide range of industrial, automotive, and consumer applications. Proper protection against environmental factors is no longer optional—it is a key requirement for modern electronic design.

English

English 中文简体

中文简体 Español

Español عربى

عربى