Evaluating If Connector Design Against Electromagnetic Interference Challenges

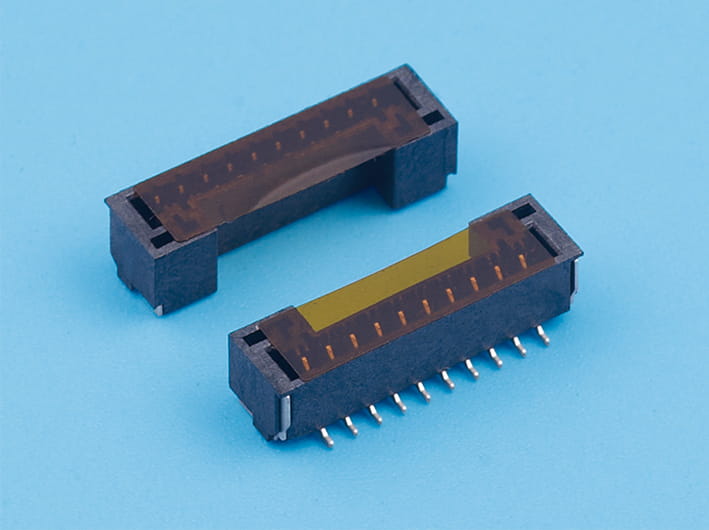

The WTB Wire to Board Connector is widely used to link discrete wiring systems to printed circuit boards, providing essential pathways for both signal and power transmission. In high-performance electronics, electromagnetic interference (EMI) is a common challenge that can severely affect data integrity, causing noise, distortions, or even complete communication failures. Since these connectors often operate in compact environments surrounded by multiple electronic components, their resistance to EMI is a key factor in determining the reliability of the overall system.

Sources of Electromagnetic Interference

To understand how a connector’s performance is influenced by EMI, it is important to recognize the sources of interference.

- Radiated Emissions: Nearby electronic components, switching power supplies, and radio frequency devices generate emissions that can couple into connector paths.

- Conducted Noise: Electrical disturbances travel along power or signal lines, entering through the connector contacts and disrupting circuits.

- Crosstalk Effects: In connectors with closely spaced terminals, signals from one line may leak into another, creating internal interference.

Structural Design Features Against EMI

Connector manufacturers employ specific design strategies to improve EMI resistance.

- Shielding Layers: Metallic housings or additional conductive shields act as barriers, reducing external radiation from penetrating the connector.

- Optimized Pin Layout: Staggered or differential signal pin arrangements reduce coupling between adjacent signal paths.

- Grounding Integration: Dedicated ground pins or ground shields inside the connector allow faster dissipation of unwanted signals.

Material and Coating Influence

The choice of materials and finishes contributes significantly to EMI protection.

- Conductive Housing Materials: Using alloys or coated plastics enhances shielding effectiveness and reduces susceptibility to external fields.

- Contact Plating: Gold or nickel plating maintains low resistance contacts, reducing the chance of signal degradation under EMI exposure.

- Dielectric Insulation: High-quality insulators maintain signal isolation and prevent energy leakage between pins.

Performance in High-Frequency Applications

As electronic systems move into gigahertz ranges, EMI effects become more pronounced, requiring connectors to maintain stability under higher demands.

- Signal Integrity Preservation: Properly designed connectors prevent jitter, delay, and distortion even in high-speed communication lines.

- Parasitic Reduction: Reducing inductance and capacitance in the connector structure reduces EMI coupling.

- Compatibility with Shielded Cables: When paired with shielded wires, the connector extends overall system EMI immunity.

Reliability Across Environments

A connector’s EMI resistance is not only determined by design but also by environmental conditions.

- Automotive Electronics: In vehicles, connectors must resist interference from ignition systems, electric motors, and onboard wireless systems.

- Industrial Applications: Heavy machinery environments require connectors that withstand high EMI levels while maintaining stable communication.

- Consumer Devices: Small-scale electronics such as smartphones need connectors with compact EMI shielding without sacrificing size efficiency.

Balancing Trade-Offs in EMI Protection

Although improving EMI resistance is beneficial, it often comes with trade-offs.

- Size vs. Shielding: Adding shielding layers may increase connector bulk, reducing suitability for ultra-compact devices.

- Cost vs. Performance: High-grade materials and coatings enhance EMI resistance but raise manufacturing costs.

- Flexibility vs. Robustness: Wire-to-board solutions must balance the need for easy assembly with the durability of shielding structures.

The effectiveness of a connector in combating electromagnetic interference depends on a combination of structural design, material selection, and environmental adaptation. The WTB Wire to Board Connector, when carefully engineered, can provide stable and reliable performance even in EMI-intensive environments. By employing shielding, grounding strategies, and high-quality materials, these connectors help safeguard high-speed and high-density electronic systems. As demands for faster data rates and more compact electronics continue to rise, EMI resistance will remain a central focus in connector development, ensuring that critical signals maintain their clarity and reliability.

English

English 中文简体

中文简体 Español

Español عربى

عربى