Connector Efficiency in the High-Speed Signal Transmission

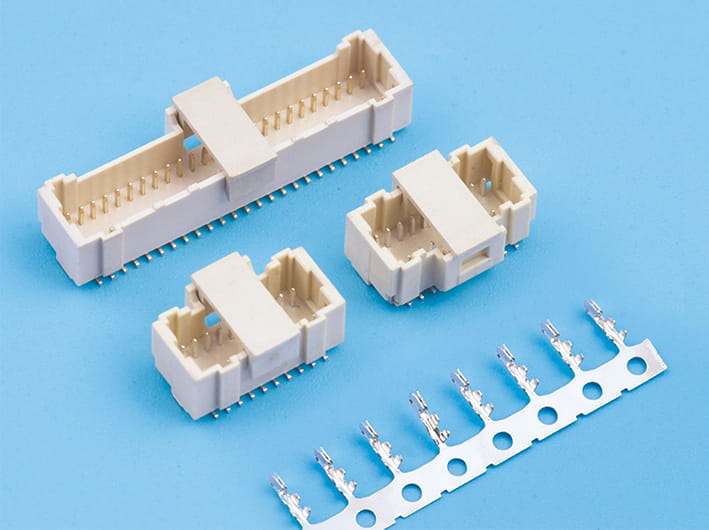

The WTB Wire to Board Connector plays an essential role in bridging discrete wiring with printed circuit boards, enabling seamless data and power transfer. In the context of high-speed signal transmission, its design and material choices significantly affect overall system integrity. As electronic devices evolve toward faster communication standards such as 5G, IoT platforms, and high-performance computing, understanding how these connectors behave under high-frequency conditions becomes crucial for system designers and engineers.

Signal Integrity Considerations

The reliability of high-speed signal transmission through a connector depends heavily on maintaining stable signal paths.

- Impedance Matching: When impedance mismatches occur between the connector and circuit traces, reflections can arise, causing signal degradation. Optimized connector geometry and materials help reduce such mismatches.

- Crosstalk Control: At high frequencies, signals traveling through adjacent contacts can interfere with each other. Proper pin layout and spacing reduce crosstalk and ensure clearer transmission.

- Attenuation Effects: Longer wiring combined with the connector interface may introduce insertion loss. Using low-resistance contacts and conductive plating reduces attenuation levels.

Impact of High-Frequency Operation

As frequencies increase, connectors face new electrical challenges.

- Electromagnetic Interference (EMI): High-speed signals generate stronger electromagnetic fields. Without proper shielding in the connector housing, EMI can leak and disrupt surrounding circuits.

- Parasitic Effects: Capacitance and inductance inherent in the connector structure distort signals at gigahertz frequencies. Design optimization helps limit parasitic influence.

- Bandwidth Limitations: Connectors with narrow paths or inconsistent geometries may cap bandwidth, restricting system performance in data-heavy applications.

Mechanical and Material Design Influence

The physical construction of a connector strongly affects its high-speed behavior.

- Contact Materials: Using gold plating or other high-conductivity finishes reduces resistance and maintains stable electrical contact over repeated use.

- Housing Structure: High-grade insulation materials reduce dielectric losses and improve high-frequency performance.

- Precision Manufacturing: Accurate alignment of terminals reduces signal discontinuities, especially critical in fine-pitch designs where high pin counts are necessary.

Thermal and Power Handling Aspects

High-speed transmission not only stresses the signal path but also introduces thermal considerations.

Heat Generation: Faster data rates often correlate with higher current demands, causing localized heating at connector interfaces.

Thermal Expansion: Materials must withstand repeated heating cycles without deforming; otherwise, mechanical shifts can degrade signal quality.

Cooling Design: Incorporating airflow-friendly connector layouts or integrating heat-resistant plastics improves long-term reliability.

Application-Specific Performance

Different industries require different balances of connector characteristics.

Consumer Electronics: Smartphones and laptops prioritize compact, lightweight connectors while demanding reliable gigabit data transfer.

Automotive Systems: Vehicles require vibration-resistant connectors capable of supporting both high-speed communication and power distribution in harsh environments.

Industrial Equipment: Connectors in automation must provide durability and stable high-speed links even in environments with electromagnetic noise and temperature fluctuations.

Balancing Trade-Offs in Design

No connector design can meet all high-speed requirements without compromise.

Miniaturization vs. Performance: Smaller connectors save space but may suffer from increased crosstalk and reduced signal clarity.

Cost vs. Reliability: Advanced materials and shielding increase costs, yet they are often necessary for consistent high-frequency performance.

Flexibility vs. Stability: Wire-to-board solutions offer flexibility but may introduce more variability compared to board-to-board connections.

The performance of a connector in high-speed signal transmission is determined by a complex balance of electrical, mechanical, and thermal factors. With increasing demand for faster, more reliable data transfer, the importance of carefully engineered connector designs continues to grow. Signal integrity, EMI control, and thermal stability remain core concerns, and manufacturers must optimize every aspect of geometry, material, and shielding. Ultimately, ensuring robust high-speed performance is not just about connecting wires to a board—it is about securing the foundation of modern digital communication systems.

English

English 中文简体

中文简体 Español

Español عربى

عربى