Understanding Connector Pin Pitch Influences Signal Transmission

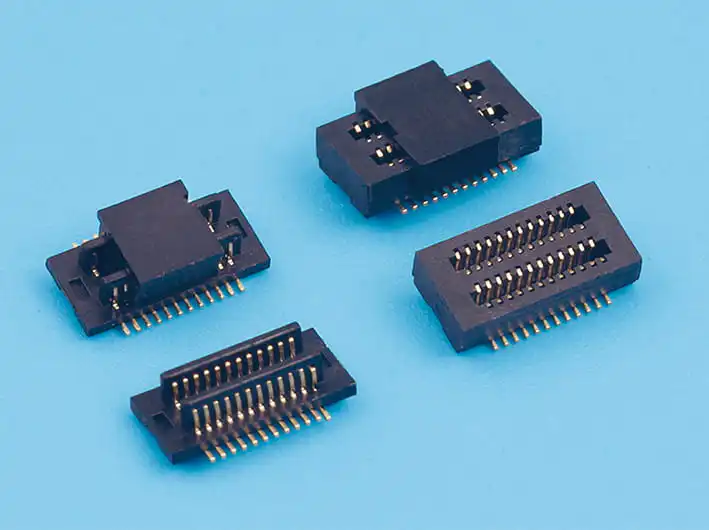

The Board to Board Connector is a critical interface in modern electronics, allowing multiple printed circuit boards (PCBs) to communicate seamlessly. One of its defining characteristics is the pin pitch, which refers to the center-to-center distance between adjacent pins. While it may appear to be a simple mechanical specification, pin pitch has a direct and profound influence on signal transmission quality, system performance, and overall reliability. As electronic devices continue to shrink in size while supporting faster data rates, understanding how pin spacing impacts signal behavior becomes increasingly important.

Influence on Signal Integrity

The spacing between pins affects how signals are transmitted through the connector.

- Crosstalk Levels: When pins are too close together, electromagnetic interference from one signal line may couple into an adjacent line, a phenomenon known as crosstalk. This can distort data, reduce clarity, and cause communication errors.

- Impedance Control: Proper pin spacing helps maintain consistent impedance across the transmission path. If spacing is irregular or too narrow, impedance mismatches can occur, causing signal reflections that degrade high-speed performance.

- Noise Reduction: Wider pin pitches provide better electrical isolation between signal paths, reducing noise coupling. This is particularly vital for sensitive analog signals and high-frequency digital communication.

Impact on High-Speed Data Transmission

As devices demand faster data transfer, pin pitch becomes even more critical.

- Bandwidth Limitations: Smaller pin spacing can limit the achievable bandwidth because of increased parasitic capacitance and inductance. These unwanted effects distort the original waveform, lowering data integrity.

- Error Rates: Narrow pitch designs increase the risk of bit errors at higher transmission speeds, especially in systems such as 5G communication devices or high-performance computing boards.

- Design Trade-Offs: While fine pitch connectors allow for miniaturization, they often require advanced signal conditioning techniques such as differential signaling, shielding, or equalization to maintain data integrity.

Mechanical and Structural Considerations

Pin pitch also affects the physical and mechanical properties of connectors.

- Density and Compactness: Smaller pin spacing allows for higher pin counts in a limited footprint, supporting multifunctional designs. This compactness is vital for consumer electronics such as smartphones and tablets.

- Manufacturing Precision: Fine pitch connectors demand high manufacturing accuracy, as even slight misalignments during assembly can compromise electrical performance.

- Durability: Wider pin pitches generally provide more robust mechanical strength, reducing the likelihood of bent or damaged pins during repeated mating cycles.

Thermal and Power Distribution Effects

Beyond signal quality, pin pitch influences thermal behavior and power handling.

- Heat Dissipation: Pins placed too closely together may trap heat, causing localized hotspots that affect reliability. Wider spacing allows better airflow and cooling between pins.

- Current Capacity: Larger spacing supports higher current-carrying capability by reducing the risk of overheating and arcing. In power-heavy applications, this is essential for ensuring safety and durability.

- Material Stress: Fine pitch connectors may concentrate stress in smaller areas, making them more susceptible to thermal expansion issues, particularly in environments with fluctuating temperatures.

Balancing Design Trade-Offs

Choosing the right pin pitch requires balancing electrical, mechanical, and application-specific needs.

- Miniaturization vs. Performance: While smaller pin spacing enables compact device designs, it may compromise signal transmission quality at higher speeds.

- Cost vs. Reliability: Fine pitch connectors often increase manufacturing costs due to tighter tolerances, whereas larger pitches may lower costs but require more space.

- Application-Specific Demands: Consumer electronics often prioritize compactness, while automotive or industrial systems emphasize reliability and robustness, causing different suitable pin spacing choices.

English

English 中文简体

中文简体 Español

Español عربى

عربى