Exploring How Connector Height and Stacking Influence Structural Design

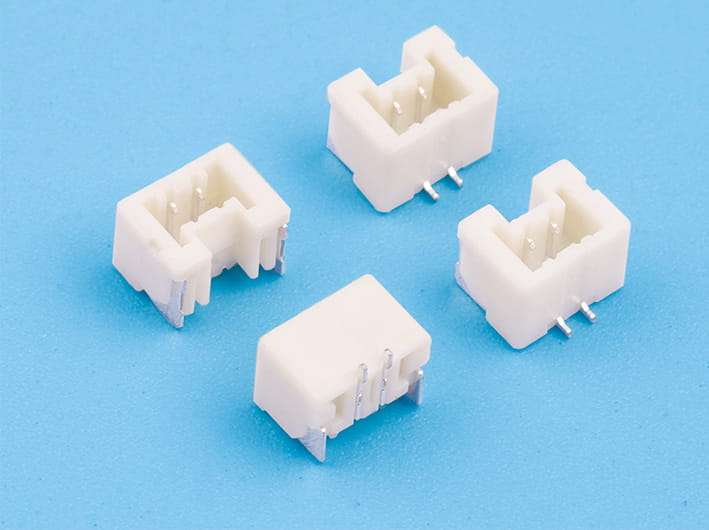

The Board to Board Connector is a critical component that allows for compact and efficient interconnection between printed circuit boards (PCBs). Among the many specifications that define its performance, the height of the connector and the way multiple boards are stacked have a profound effect on the overall structure. These parameters directly influence spatial organization, mechanical stability, thermal management, and signal routing. Understanding how connector height and stacking configurations impact structural design is essential for achieving a balance between reliability, miniaturization, and performance.

Impact of Connector Height on Structural Layout

Connector height plays a key role in determining how PCBs are arranged within a device.

- Space Utilization: A taller connector creates more clearance between boards, which can accommodate larger components, heat sinks, or airflow channels. Conversely, lower-profile connectors save vertical space, enabling thinner and lighter product designs.

- Mechanical Stability: Height affects the mechanical leverage applied when a device is subjected to stress. Low connectors generally provide greater resistance to bending or vibration, while taller connectors may require reinforcement to ensure long-term durability.

- Ease of Assembly: Higher connectors allow easier access for manual or automated assembly processes, reducing the risk of misalignment during installation. Shorter connectors, while compact, may demand greater precision during soldering and placement.

Influence of Stacking Methods on Design

Stacking refers to the way multiple boards are interconnected through connectors. Different stacking arrangements affect system architecture in distinct ways.

- Parallel Stacking: This common approach involves boards being mounted directly above one another, separated by a uniform connector height. It creates a layered system, useful in smartphones and tablets, where space optimization is crucial.

- Orthogonal Stacking: Boards are connected at right angles, which can simplify signal routing and improve electromagnetic compatibility by isolating functional sections. However, this method may increase the footprint of the overall design.

- Custom Stacking Configurations: In complex systems such as servers or automotive electronics, boards may be staggered or arranged asymmetrically. These designs often aim to balance cooling, structural rigidity, and accessibility for maintenance.

Thermal and Electrical Considerations

The choice of height and stacking not only affects physical layout but also thermal and electrical performance.

- Heat Dissipation: Taller connectors that create more spacing allow airflow to pass between layers, improving heat dissipation. Compact stacks, while space-efficient, may require additional cooling solutions to prevent hotspots.

- Signal Integrity: Longer electrical paths introduced by taller connectors can increase signal delay or introduce noise. Proper height selection ensures that high-speed signals maintain integrity without unnecessary interference.

- Power Distribution: Stacking orientation determines how power planes and ground connections are routed, influencing both stability and efficiency in power delivery.

Balancing Design Trade-Offs

Designers must carefully weigh the trade-offs between connector height, stacking methods, and structural requirements.

- Miniaturization vs. Durability: Thin devices prioritize low-profile connectors, but may face challenges in handling vibration or thermal expansion.

- Performance vs. Cost: Custom stacking arrangements can optimize performance but may increase manufacturing complexity and expenses.

- Flexibility vs. Precision: Greater clearance provides flexibility for component placement, yet tighter stacks often demand higher precision in design and assembly.

The height and stacking method of connectors have a decisive impact on structural design in modern electronics. By influencing space utilization, mechanical stability, heat management, and signal transmission, these parameters shape not only the internal layout but also the external form factor of devices. Achieving a suitable balance requires considering both functional demands and practical limitations. As electronic products continue to evolve toward smaller, faster, and more reliable systems, connector height and stacking strategies will remain central factors guiding structural design decisions.

English

English 中文简体

中文简体 Español

Español عربى

عربى