High-Speed Signal WTB Connectors: Key Electrical Characteristics

Introduction to High-Speed Connector Challenges

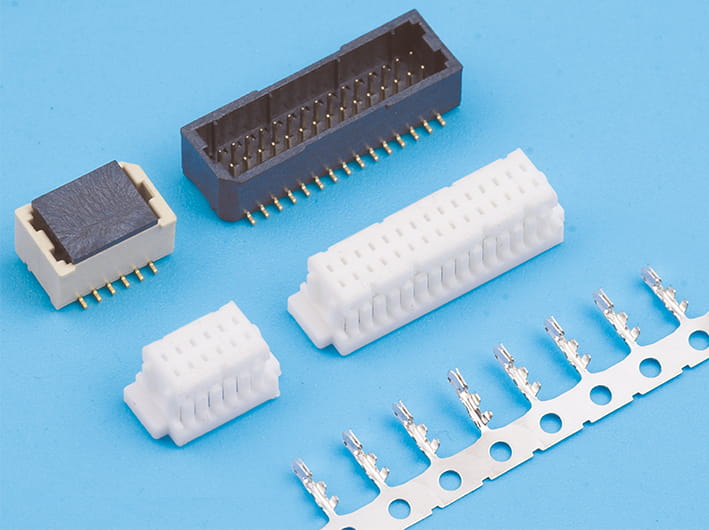

The WTB Wire to Board Connector plays a crucial role in connecting cables to printed circuit boards while maintaining signal integrity. In high-speed applications, such as data communication, industrial automation, or advanced consumer electronics, the electrical characteristics of the connector can significantly impact overall system performance. Improper selection or installation can cause signal degradation, increased crosstalk, or electromagnetic interference (EMI), compromising device functionality. Understanding these factors is essential for engineers to ensure reliable and efficient high-speed data transmission.

Impedance Matching

Importance of Characteristic Impedance: High-speed signals are sensitive to impedance mismatches. WTB Wire to Board Connectors must maintain consistent impedance along the signal path to prevent reflections and signal loss.

Connector Design for Matching: Connectors designed with controlled geometry, spacing between pins, and optimized trace layouts help maintain impedance consistency. When designing a PCB layout for the connector, engineers must match the connector impedance with the transmission line to reduce return loss and maintain signal integrity.

Crosstalk and Signal Coupling

Reducing Crosstalk: Crosstalk occurs when a signal from one channel interferes with a neighboring channel. High-speed WTB connectors should feature proper pin spacing, ground pins, and shielding techniques to reduce coupling between adjacent conductors.

Differential Pair Considerations: For differential signals, the connector should preserve the spacing and pairing throughout the connection. Maintaining a consistent differential impedance reduces noise and ensures accurate signal transmission.

Insertion Loss and Return Loss

- Insertion Loss: High-speed connectors introduce some signal attenuation. The selection of low-loss WTB Wire to Board Connectors is critical, especially at higher frequencies. Connector material, plating, and contact resistance influence the degree of insertion loss.

- Return Loss: Return loss measures how much signal is reflected toward the source. A well-designed connector reduces reflections, preserving the amplitude and integrity of transmitted signals. Engineers often use simulation tools to evaluate return loss across frequency ranges before finalizing connector selection.

Electromagnetic Compatibility (EMC)

- Shielding and Grounding: Proper grounding and optional shielding of WTB connectors help prevent EMI and ensure EMC compliance. High-speed signals are particularly susceptible to external noise, which can be transmitted through the connector if not properly managed.

- PCB Layout Strategies: Positioning ground traces and planes near the connector pins reduces radiated emissions and enhances signal quality. Careful routing reduces loops and potential EMI coupling between power and signal lines.

Contact Resistance and Reliability

- Importance of Low Contact Resistance: High-speed signals are sensitive to small voltage drops caused by contact resistance. WTB Wire to Board Connectors must use high-quality materials and plating, such as gold or nickel, to maintain low resistance and long-term performance.

- Mechanical Stability: Vibration, insertion, and repeated mating cycles can affect contact integrity. Choosing connectors with robust latching mechanisms and stable contacts ensures consistent electrical performance over time.

Temperature and Environmental Considerations

- Temperature Effects: High-speed connectors can experience signal degradation if materials expand or contract with temperature changes. Selecting materials with stable dielectric properties ensures variation in impedance.

- Moisture and Contaminants: Environmental factors such as humidity and dust can introduce leakage paths and increase insertion loss. Protective features and controlled environments help maintain reliable high-speed performance.

Designing for High-Speed Performance

WTB Wire to Board Connector selection for high-speed applications requires careful attention to impedance matching, crosstalk reduction, insertion and return loss, EMC management, and long-term reliability. Proper material choice, pin layout, and connector design all contribute to maintaining signal integrity. By addressing these electrical characteristics, engineers can ensure that high-speed connections perform reliably, supporting efficient data transmission and robust system operation in demanding applications.

English

English 中文简体

中文简体 Español

Español عربى

عربى