Evaluating and Optimizing BTB Power Connector EMI Performance

Introduction to Interference in Power Connectors

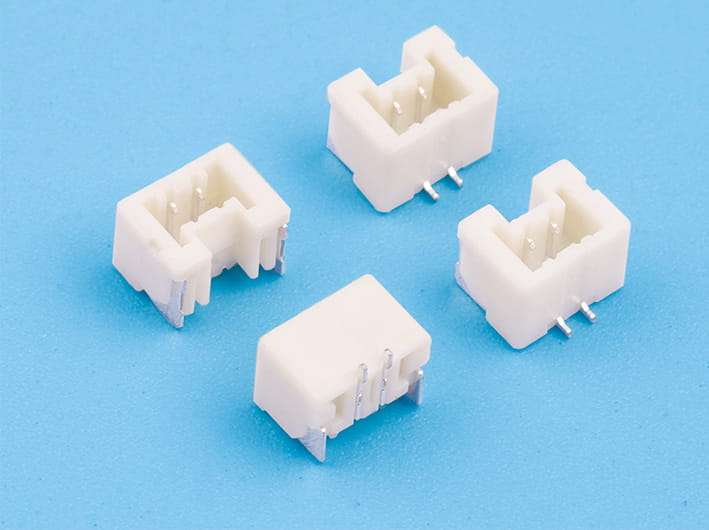

The BTB Power Connector is widely used in electronic systems to provide reliable board-to-board power transmission. However, high currents and fast switching in modern electronics can generate electromagnetic interference (EMI), affecting both the connector and surrounding circuitry. Poor EMI performance can cause signal degradation, equipment malfunction, or regulatory compliance issues. Evaluating and optimizing interference performance is therefore critical for both designers and system integrators.

Understanding Sources of EMI

- Conducted Noise: Power connectors carry high currents, and rapid changes in current can create voltage fluctuations and conducted noise along traces. This noise can propagate through the PCB and connected devices.

- Radiated Noise: Physical layout and insufficient shielding can cause the connector and associated traces to act as antennas, emitting EMI into nearby circuits. High-speed switching power components exacerbate this effect.

- Crosstalk Between Pins: Closely spaced pins carrying power and signal lines may induce unwanted coupling, which increases susceptibility to interference. Proper pin assignment and grounding help mitigate this risk.

Evaluating EMI Performance

- Laboratory Testing: Use standardized tests such as CISPR 22 or IEC 61000 to measure radiated and conducted emissions from the connector. Specialized test setups simulate operating conditions, including full load current and environmental influences.

- Simulation Tools: Electromagnetic simulation software allows engineers to model the connector, PCB layout, and surrounding components to predict EMI behavior. This method helps identify critical design points before physical prototyping.

- Signal Integrity Measurement: Analyze voltage fluctuations, impedance mismatches, and coupling between traces to assess potential interference. Oscilloscopes and spectrum analyzers provide quantitative insight into connector performance.

Design Strategies for EMI Optimization

- Grounding and Shielding: Adding ground pins near power pins and implementing shielding over the connector helps contain radiated emissions. For sensitive systems, a metal housing or grounded cage around the connector may be employed.

- Pin Layout Optimization: Separate high-current pins from signal lines to reduce crosstalk. Placing ground pins strategically between power and signal pins acts as a barrier, lowering EMI coupling.

- Trace and Plane Design: Wide traces for power reduce voltage fluctuations and resistive losses. Connecting the power and ground pads to internal planes improves current return paths and reduces loop area, reducing radiated emissions.

Material and Manufacturing Considerations

- Contact Material and Plating: Using high-conductivity materials such as gold-plated contacts reduces resistance and heating, limiting noise generation.

- Connector Housing Design: Insulating materials with low dielectric loss prevent unintended coupling and reduce EMI effects. Ensure tight tolerances to avoid gaps that can radiate noise.

- Insertion Stability: Secure latching mechanisms prevent micro-movements that can create intermittent connections, which are a significant source of EMI.

System-Level Optimization

- Decoupling Capacitors: Place capacitors near the BTB Power Connector to smooth voltage fluctuations and filter high-frequency noise.

- Filtering Components: Integrating ferrite beads or EMI filters on power lines can attenuate unwanted noise before it spreads to other parts of the system.

- PCB Layout Considerations: Reducing loop areas, maintaining controlled impedance, and optimizing trace routing contribute to better EMI performance at the system level.

The EMI performance of the BTB Power Connector is influenced by pin layout, grounding, shielding, trace design, materials, and system-level integration. Proper evaluation through testing and simulation, combined with thoughtful design and component selection, can significantly reduce interference risks. By applying these optimization strategies, engineers can achieve reliable, compliant, and high-performance power connections in demanding electronic applications.

English

English 中文简体

中文简体 Español

Español عربى

عربى