Advantages and Challenges of Board to Board Connectors

Introduction to High-Density and Multi-Layer PCB Designs

High-density and multi-layer PCB designs are increasingly common in modern electronics, including smartphones, laptops, and industrial equipment.

These designs aim to improve functionality while reducing device size, requiring sophisticated interconnect solutions.

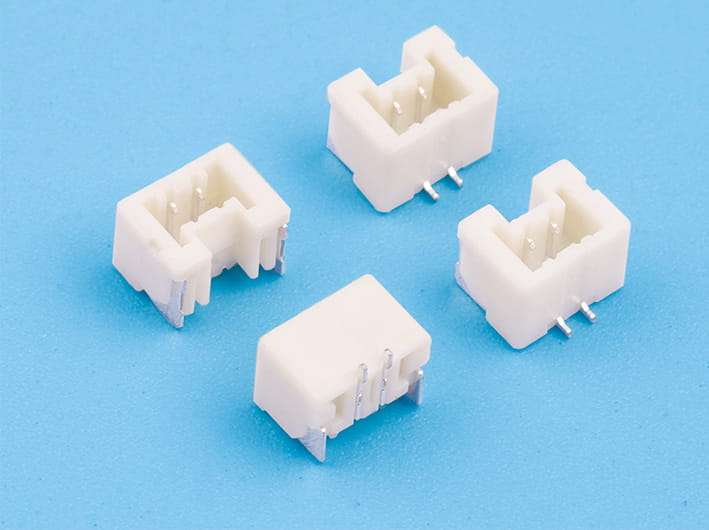

Board to Board Connector is a crucial component enabling reliable electrical and mechanical connections between stacked or parallel PCBs.

Advantages of Board to Board Connectors in Dense Designs

- Space Efficiency:

- Enables vertical stacking of PCBs, reducing overall device footprint.

- Eliminates the need for long wiring harnesses, saving both space and weight.

- High Pin Density:

- Supports a large number of signals in a compact connector footprint.

- Allows for multiple power, ground, and signal lines without increasing board area.

- Simplified Assembly:

- Reduces the complexity of routing traces between PCBs compared to wire harnesses.

- Standardized connectors streamline manufacturing and assembly processes.

- Reliable Electrical Performance:

- Provides stable contact for high-speed signals and power delivery.

- Consistent impedance control reduces signal reflection and crosstalk in high-frequency designs.

- Flexibility in Modular Design:

- Facilitates modular PCB layouts, making it easier to upgrade or replace individual boards.

- Supports multi-functional boards within the same device without redesigning the entire PCB.

Challenges in High-Density and Multi-Layer Applications

1. Alignment and Tolerance Issues:

Precise mechanical alignment is crucial; even minor misalignment can cause intermittent contact or failure.

Manufacturing tolerances for multi-layer boards and connectors must be carefully controlled.

2. Thermal and Mechanical Stress:

High-density configurations can generate heat, potentially affecting connector reliability.

Stacked boards may experience mechanical stress during handling or vibration, requiring robust connector design.

3. Signal Integrity Concerns:

High-speed signals are susceptible to crosstalk and EMI in closely packed connectors.

Maintaining controlled impedance is challenging when multiple layers and connectors are used in tight spaces.

4. Limited Accessibility:

Once stacked, individual boards can be difficult to access for testing or repair.

Maintenance and troubleshooting require connectors that support easy disassembly without damage.

5. Cost Considerations:

High-density and high-pin-count connectors are generally more expensive than standard solutions.

Increased manufacturing complexity can raise overall production costs.

Design Considerations for Suitable Performance

Connector Pitch and Pin Count:

- Smaller pitch supports higher pin density but may increase the risk of shorts or manufacturing defects.

- Proper selection ensures compatibility with board layout and signal requirements.

Material Selection:

- High-quality metals and durable plastics improve mechanical reliability and signal performance.

- Plating choices, such as gold or tin, affect longevity and contact resistance.

Stacking Height and Orientation:

- Careful planning of PCB spacing prevents mechanical interference and ensures sufficient airflow.

- Connector orientation affects assembly, thermal management, and accessibility.

Environmental Protection:

- Consider moisture-resistant coatings or seals for boards exposed to humid or harsh environments.

- Helps maintain electrical reliability and reduces the risk of corrosion.

Testing and Validation for Multi-Layer Configurations

- Insertion and Retention Testing:

Ensures connectors maintain proper contact under mechanical stress.

Validates that stacked boards can be inserted and removed without damage.

- Signal Integrity Testing:

Time-domain reflectometry (TDR) and other high-speed tests confirm proper impedance and crosstalk.

- Thermal Cycling:

Simulates operational temperature variations to verify long-term reliability.

Vibration and Shock Testing:

Assesses the mechanical durability of connectors in portable or industrial devices.

Practical Applications in Modern Electronics

- Consumer Devices: Smartphones and laptops benefit from vertical stacking to save space and improve modularity.

- Automotive Electronics: Engine control units (ECUs) and infotainment systems rely on robust board-to-board connections to withstand vibration and temperature extremes.

- Industrial Equipment: Modular controllers and communication boards require high pin density and reliable connections in confined spaces.

- Medical Devices: Compact, high-performance connectors allow multi-layer PCB designs in portable diagnostic or monitoring equipment.

Board to Board Connector provides clear advantages for high-density and multi-layer PCB designs, including space efficiency, high pin density, and reliable electrical performance.

However, designers must address challenges such as alignment, thermal stress, signal integrity, and cost considerations.

Through careful design, material selection, and rigorous testing, these connectors enable compact, modular, and high-performance electronic systems.

As devices continue to miniaturize and integrate more functionality, the role of board-to-board interconnects becomes increasingly critical for achieving both performance and reliability.

English

English 中文简体

中文简体 Español

Español عربى

عربى