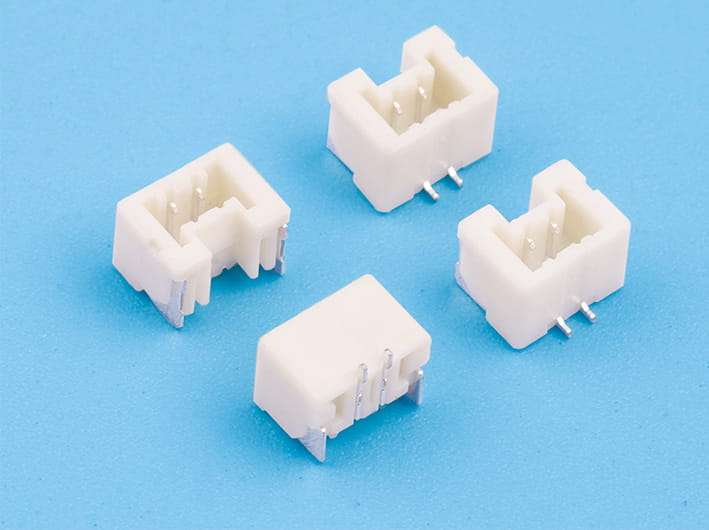

Thermal Performance Considerations When Selecting Board to Board Power Connectors

Operating Challenges in High-Temperature Environments

In modern electronic systems, especially those used in sectors such as automotive, aerospace, and industrial automation, components are often exposed to elevated temperatures that can significantly impact their performance. A Board to Board Power Connector, tasked with carrying current and signals between printed circuit boards, must maintain its electrical and mechanical integrity even when ambient conditions exceed standard temperature thresholds. Whether due to internal heat generation or external environmental factors, the ability to function reliably at high temperatures is crucial to overall system performance and longevity.

Material Stability and Insulation Performance

The foundation of thermal resistance in any connector begins with the choice of materials. Housing components are typically made from high-temperature thermoplastics such as LCP (liquid crystal polymer) or PPS (polyphenylene sulfide), which can withstand prolonged exposure to temperatures upwards of 260°C without deforming or degrading. These materials offer dimensional stability, ensuring the connector maintains its shape and fit under thermal expansion. Insulation resistance is another critical aspect, as high temperatures can reduce dielectric strength, potentially causing leakage currents or short circuits. Quality materials and proper design help preserve insulation values even under thermal stress.

Contact Materials and Resistance to Oxidation

Electrical contacts within connectors are often made from copper alloys, which offer good conductivity. However, at elevated temperatures, metal surfaces can oxidize or corrode, causing increased contact resistance and eventual signal degradation. To prevent this, contacts are plated with precious metals such as gold or palladium, which resist oxidation and maintain low contact resistance over extended use. Spring force is also engineered to compensate for material softening at higher temperatures, ensuring that contact pressure remains consistent and that electrical continuity is not compromised during thermal cycling.

Thermal Cycling and Expansion Stress

High-temperature performance isn’t solely about surviving a single thermal threshold—it also involves withstanding repeated heating and cooling cycles. These thermal cycles can induce mechanical stress due to the differing expansion coefficients of connector materials and PCB substrates. Over time, this may cause micro-cracks, solder joint fatigue, or mechanical loosening. To address this, high-performance connectors are designed with flexible contact geometries and mounting features that allow for thermal expansion without exerting excessive stress on the solder joints or housing structures. Some designs include floating contacts or compliant pins that adapt to dimensional changes during operation.

Long-Term Reliability and Industry Standards

Many industries have set standardized thermal benchmarks to evaluate connector reliability in high-temperature conditions. Tests such as IEC 60512 or UL 1977 evaluate a connector’s ability to maintain contact resistance, mechanical retention, and insulation integrity after prolonged exposure to high heat. These assessments often simulate years of operational wear in just weeks. When a connector passes such rigorous testing, it indicates that it can provide stable performance even in environments such as engine compartments, power converters, or industrial furnaces, where temperature fluctuations are continuous.

Building Confidence Through Thermal Design Well

In temperature-sensitive applications, the thermal resilience of a Board to Board Power Connector is a decisive factor in ensuring reliable operation and long-term durability. By combining heat-resistant materials, oxidation-resistant contact finishes, thermally adaptive structural designs, and validated testing procedures, manufacturers can produce connectors that perform consistently even in thermally hostile environments. This ensures that sensitive electronics remain protected and operational, no matter how intense the heat becomes.

English

English 中文简体

中文简体 Español

Español عربى

عربى