Design Strategies for Vibration and Impact Resistance in Board to Board Power Connectors

The Importance of Mechanical Stability in Modern Electronic Systems

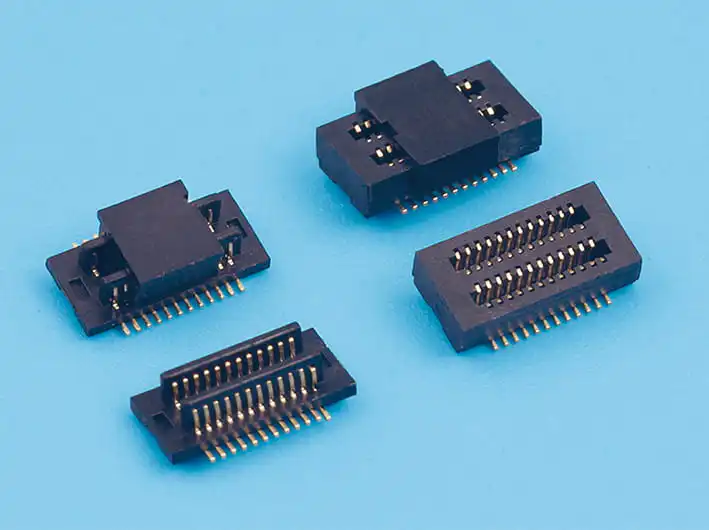

In high-reliability applications such as automotive electronics, aerospace control systems, industrial automation, and transportation infrastructure, mechanical stability is as crucial as electrical performance. While the Board to Board Power Connector serves as a vital bridge for transmitting current and signals between printed circuit boards, its long-term functionality also heavily depends on its ability to endure harsh physical environments. Vibration and shock are particularly damaging forces that can compromise contact integrity, weaken housing structures, and ultimately cause system failure. Therefore, ensuring that connectors can resist these forces is fundamental in mission-critical designs.

Structural Engineering and Contact Retention Features

To address the challenge of maintaining reliable connections under continuous movement or sudden impacts, advanced structural engineering is applied to the connector's design. One of the measures is the use of robust housing materials such as high-temperature thermoplastics and reinforced composites, which resist deformation and cracking. In addition, contact retention systems play a major role in securing the pins within the housing. These systems often use dual-beam or quad-beam spring contacts that maintain consistent pressure and offer redundancy in case of partial misalignment. Enhanced mating force and firm contact engagement further prevent fretting or micro-movements that could otherwise cause intermittent electrical behavior.

Shock and Vibration Testing Protocols and Standards

Manufacturers subject board-level connectors to rigorous mechanical reliability tests that simulate real-world stress conditions. These include vibration tests based on standards like IEC 60512-6-4 or MIL-STD-202, where the connector is exposed to varying frequencies and amplitudes across three axes. For shock testing, mechanical pulses with high G-forces are applied in short durations to replicate events such as drops or sudden impacts. During these tests, performance metrics such as contact resistance variation, insulation integrity, and mechanical fatigue are carefully monitored. A connector that meets or exceeds such standards offers greater confidence in environments where vibration and shock are unavoidable.

Mounting Methods and Board Design to Reduce Stress

Even the designed connector must be integrated into a circuit board layout that complements its vibration resistance. Surface mount or through-hole soldering techniques must ensure proper anchoring of the connector to prevent loosening over time. In many designs, mechanical fasteners or board locks are used to distribute stress and keep the connector securely in place. Additionally, the spacing and alignment of connectors between stacked boards are optimized to prevent flexing and to allow the system to move as a unified body under mechanical stress. Dampening materials or gaskets may also be applied around the connector zone to absorb residual energy from shock or vibration.

Application-Specific Enhancements for Rugged Environments

Certain applications demand custom or semi-custom enhancements for enhanced durability. This can include additional sealing for moisture and dust protection, which also helps reduce particle-related wear during vibration. In railways, connectors are often shielded with metal enclosures to add rigidity and electromagnetic protection. In automotive systems, connectors may feature locking mechanisms that prevent unmating even under severe vibration conditions. The adoption of these specialized components ensures that connectors can serve reliably over millions of cycles in difficult environments, supporting both electrical performance and mechanical robustness.

Engineering Confidence Through Mechanical Reliability

While electrical efficiency remains a core requirement, the mechanical performance of a Board to Board Power Connector is equally vital when deployed in vibration-prone or high-impact scenarios. Through deliberate material selection, optimized contact designs, rigorous testing, and careful integration into board layouts, manufacturers achieve connectors that not only transfer power reliably but also endure the physical stress of real-world applications. This combination of electrical function and mechanical resilience ensures that critical systems remain stable, safe, and operational under demanding conditions.

English

English 中文简体

中文简体 Español

Español عربى

عربى