Stability of WTB Wire to Board Connector Under Vibration and Shock Conditions

Connectors must perform reliably even under some conditions. Devices used in automotive, aerospace, industrial, and military applications are often exposed to constant vibration, sudden shocks, and mechanical stress. Ensuring that the electrical connection remains stable is critical for maintaining system functionality and safety. The WTB Wire to Board Connector is designed to provide secure electrical connections, but its performance under vibration and impact requires careful evaluation. Understanding its design features and operational limits is essential for engineers selecting connectors for high-stress environments.

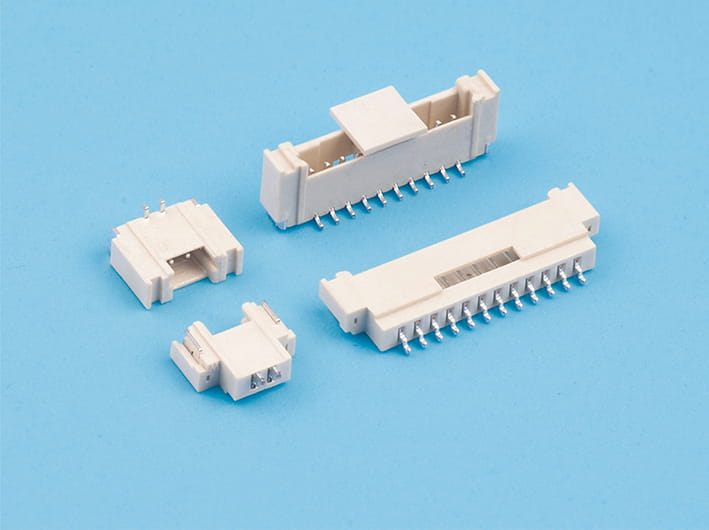

Mechanical Design and Locking Features

A key factor influencing stability under vibration is the mechanical design of the connector. WTB Wire to Board Connectors typically incorporate secure locking mechanisms, such as latch locks or friction-based retention, which prevent accidental disengagement. These features help maintain proper alignment between the wire and the PCB even when the device is subjected to repeated shocks or continuous vibration. The precision of the mating interface, the robustness of the housing, and the quality of the materials used all contribute to reducing the risk of connection loss.

Contact Reliability Under Vibration

Electrical contact stability is just as important as mechanical retention. The connector’s contact terminals are often engineered to maintain consistent pressure against the mating surface, ensuring uninterrupted conductivity. Spring-loaded or compliant contacts can absorb minor movements caused by vibration, reducing the likelihood of intermittent signals or connection failures. In addition, surface finishes such as gold plating can enhance conductivity while resisting corrosion, which further improves reliability in environments prone to mechanical stress.

Testing and Certification Standards

WTB Wire to Board Connectors are typically tested according to industry standards to verify performance under vibration and shock conditions. These tests simulate real-world scenarios, including prolonged sinusoidal vibration, random vibration, and drop impact tests. Compliance with standards such as IEC 60068 or MIL-STD-202 ensures that the connector can withstand mechanical stresses without compromising electrical integrity. Test results provide engineers with the data needed to select connectors suitable for critical applications where failure is not an option.

Applications Requiring High Stability

Certain industries demand good connector stability due to operational requirements. In automotive electronics, connectors experience engine vibrations, road shocks, and temperature fluctuations. In aerospace, connectors must endure high-frequency vibrations during flight and mechanical stress during takeoff and landing. Industrial machinery often subjects connectors to both continuous vibration and occasional impact from moving parts. In these scenarios, WTB Wire to Board Connectors are designed to maintain both electrical and mechanical stability, ensuring uninterrupted system performance.

Maintenance and Installation Considerations

Proper installation is crucial to achieving stability under vibration. Ensuring that the connector is fully seated, locked, and aligned reduces the risk of loosening over time. Routine inspections and preventive maintenance can identify wear, deformation, or contamination that could compromise connection stability. Using connectors with vibration-resistant features and following recommended installation procedures helps extend operational life and reliability in demanding environments.

Ensuring Reliable Connections Under Mechanical Stress

The WTB Wire to Board Connector offers a combination of secure mechanical locking and reliable contact design, making it suitable for applications exposed to vibration and shock. Its engineered features, including latch mechanisms, compliant contacts, and durable materials, provide consistent electrical performance even under repeated mechanical stress. Proper installation, adherence to standards, and consideration of environmental conditions are essential for improving stability. In demanding industrial, automotive, and aerospace applications, selecting connectors with proven vibration and shock resistance ensures system reliability and long-term operational safety.

English

English 中文简体

中文简体 Español

Español عربى

عربى