Compatibility of WTB Wire to Board Connector with Various PCB Types

Introduction to PCB Compatibility Challenges

In modern electronics, printed circuit boards (PCBs) vary widely in size, material, layer count, and layout. Ensuring reliable electrical connections across different PCB types is a critical factor in product design and assembly. The WTB Wire to Board Connector is designed to facilitate efficient connections between wires and PCBs, but its compatibility with diverse board types must be carefully considered. Understanding its adaptability helps engineers achieve secure, reliable connections while reducing potential issues during production or operation.

Physical Design and Mounting Flexibility

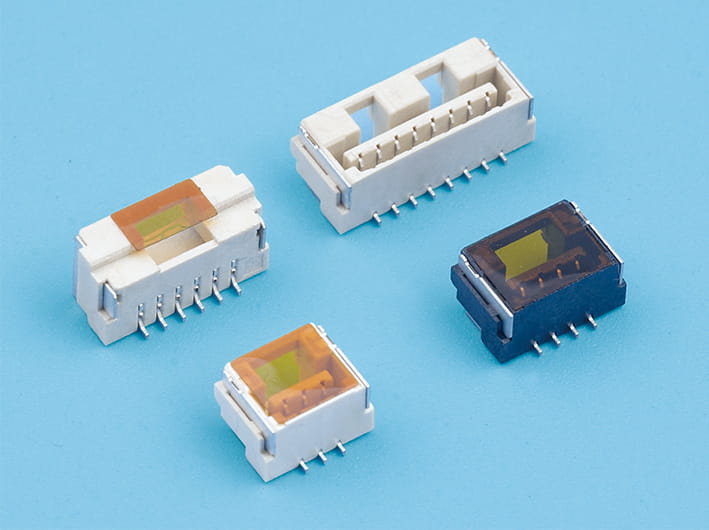

The physical design of the connector plays a key role in compatibility. WTB Wire to Board Connectors are often available in through-hole and surface-mount configurations, allowing them to adapt to different PCB designs. Through-hole connectors provide strong mechanical support for boards subject to vibration or mechanical stress, while surface-mount versions enable compact layouts and high-density assembly. The variety of pin spacing, row configurations, and mounting styles ensures that the connector can interface with multiple PCB geometries without compromising stability or alignment.

Electrical Considerations Across PCB Types

Compatibility also depends on electrical characteristics. PCBs differ in copper trace thickness, dielectric material, and layer count, which affect current-carrying capacity and voltage tolerance. WTB Wire to Board Connectors are designed to provide consistent contact resistance and secure conductivity across various PCB substrates, including FR-4, polyimide, and high-frequency laminates. Proper matching of connector specifications with PCB electrical parameters ensures that the system maintains suitable performance without overheating, voltage drop, or signal degradation.

Mechanical Stability and Reliability

Different PCB types present unique mechanical challenges. Flexible PCBs, for example, require connectors that can accommodate slight movement without losing contact, while rigid, multi-layer boards demand connectors with precise alignment and robust mechanical retention. The WTB Wire to Board Connector incorporates features such as locking mechanisms and compliant contacts that enhance reliability across these diverse board types. These design elements reduce the risk of disconnections, even under vibration, thermal cycling, or mechanical stress.

Design Integration and Layout Considerations

Compatibility extends beyond electrical and mechanical aspects to overall design integration. WTB connectors support various row configurations and footprint options, allowing designers to efficiently integrate them into complex PCB layouts. This adaptability simplifies routing, reduces assembly errors, and facilitates automated manufacturing processes. By selecting a connector that matches both the PCB footprint and the electrical requirements, engineers can streamline production while maintaining long-term reliability.

Testing and Validation for Multiple PCB Types

Before deployment, connectors are typically validated with different PCB materials and designs. Testing includes insertion and extraction cycles, vibration and shock tests, and electrical continuity measurements. WTB Wire to Board Connectors are engineered to perform consistently during these tests, demonstrating compatibility with a wide range of board thicknesses, materials, and configurations. These validation procedures give manufacturers confidence that the connectors will maintain secure electrical connections throughout the product’s lifecycle.

Ensuring Reliable Connections Across PCB Variations

The WTB Wire to Board Connector provides versatile compatibility with various PCB types, offering flexible mounting options, robust electrical performance, and mechanical reliability. Its design supports multiple PCB materials, thicknesses, and configurations, ensuring stable connections even in demanding applications. By understanding these compatibility factors, engineers can select the right connector for their PCB design, enhancing system performance, simplifying assembly, and ensuring long-term operational reliability. Selecting connectors with proven adaptability is therefore essential for modern electronic applications where PCB diversity is increasingly common.

English

English 中文简体

中文简体 Español

Español عربى

عربى