An In-Depth Analysis of the Connection Stability of Board to Board Power Connectors

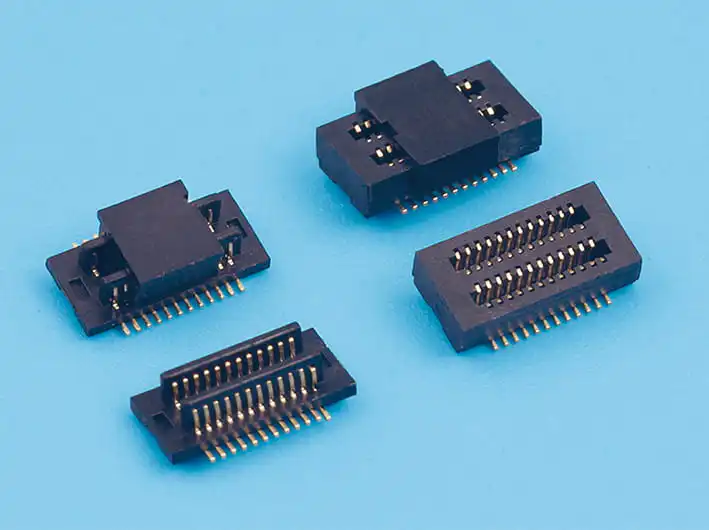

High Quality Board to Board Power Connector Manufacturer

In the intricate world of electronics, the stability of connections is paramount, and this is especially true for Board to Board Power Connectors. These connectors play a pivotal role in ensuring the seamless transfer of power and signals between circuit boards, which is crucial for the operation of a wide array of electronic devices. The reliability and stability of Board to Board Power Connectors are often the difference between a device functioning flawlessly or failing unexpectedly. This article will explore the various factors that contribute to the connection stability of these connectors and how they are engineered to maintain performance in various conditions.

Board to Board Power Connectors are designed with precision engineering to provide a secure and stable connection between two or more circuit boards. The stability of these connectors is achieved through a combination of mechanical design, materials selection, and manufacturing processes. The connectors must be able to maintain their structural integrity and electrical conductivity over time, even when subjected to repeated mating and unmating cycles, as well as under varying environmental conditions.

One of the key aspects of Board to Board Power Connector stability is the contact force exerted by the connector pins. This force ensures a consistent and reliable electrical connection, preventing intermittent or poor connections that could cause signal loss or power failure. The design of the connector housing also plays a significant role in maintaining stability. Robust housing can resist physical stress and prevent the pins from becoming misaligned or damaged, which could compromise the connection.

Material selection is another critical factor in the stability of Board to Board Power Connectors. Connectors made from materials with high thermal and electrical conductivity, such as gold or copper, can provide a stable and efficient connection. Additionally, the use of materials that are resistant to corrosion and wear can enhance the longevity and reliability of the connectors in harsh environments.

The manufacturing process also has a significant impact on the stability of Board to Board Power Connectors. High-quality manufacturing practices ensure that each connector is consistent in its dimensions and performance, reducing the likelihood of defects that could cause connection issues. Precision machinery and stringent quality control measures are essential to produce connectors that meet the exacting standards required for reliable performance.

Environmental factors, such as temperature and humidity, can also influence the stability of Board to Board Power Connectors. Connectors designed for use in bad environments must be able to withstand temperature fluctuations without losing their structural integrity or electrical conductivity. Sealing mechanisms and protective coatings can be employed to shield the connectors from moisture and other environmental contaminants that could affect their performance.

In conclusion, the connection stability of Board to Board Power Connectors is a complex interplay of design, materials, manufacturing, and environmental considerations. By understanding these factors, manufacturers can produce connectors that provide reliable and stable connections in a variety of applications. The ongoing development and refinement of Board to Board Power Connector technology ensure that these connectors will continue to play a vital role in the ever-evolving world of electronics, providing the stable connections that power our modern devices.

English

English 中文简体

中文简体 Español

Español عربى

عربى