Understanding Board to Board Power Connector Compatibility with Pitch and Board Thickness

Board to Board Power Connectors are essential components in modern electronics, providing reliable electrical connections between printed circuit boards (PCBs). One of the critical factors for their proper selection and performance is the compatibility with board-to-board spacing, commonly referred to as pitch, as well as the thickness of the PCBs being connected. Selecting a connector with the appropriate pitch and board thickness specifications ensures secure mechanical engagement, reliable electrical conductivity, and long-term durability, particularly in high-power or high-density applications.

The Importance of Pitch in Board-to-Board Connections

Pitch refers to the distance between the centers of adjacent connector pins or terminals. This measurement directly impacts both electrical performance and mechanical fit. A connector with a pitch that matches the design of the PCB ensures precise alignment, reducing the risk of misalignment, short circuits, or signal loss. Smaller pitch connectors are often used in compact, high-density applications where space is limited, while larger pitch connectors can handle higher current loads and provide more robust mechanical strength. Understanding the required pitch for the specific board design is essential for both performance and safety.

Considerations for Board Thickness

The thickness of the PCB also plays a crucial role in connector compatibility. Thicker boards can support larger connectors and provide greater mechanical stability, which is important for applications subjected to vibration, thermal cycling, or repeated handling. Conversely, thinner boards may require connectors with specialized mounting mechanisms or reinforced housings to prevent damage or warping. Board thickness also affects the insertion depth of the connector, which in turn influences the stability of the electrical contact and the overall durability of the connection.

Mechanical Design for Different Pitches and Thicknesses

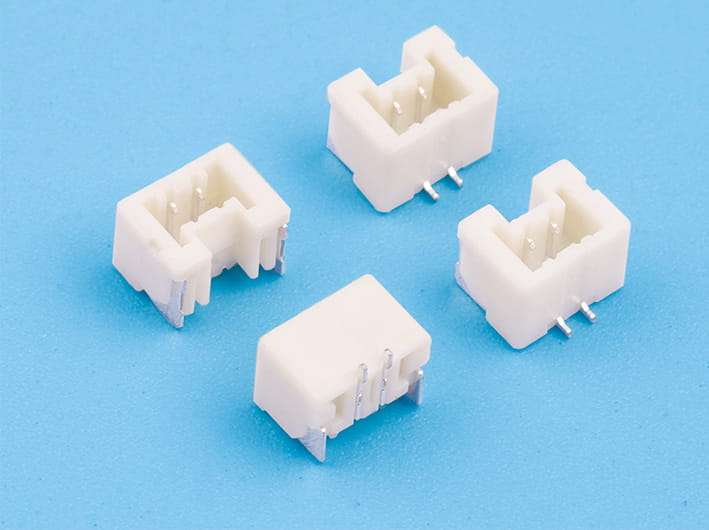

Board to Board Power Connectors are designed with various mechanical features to accommodate different pitches and board thicknesses. These include adjustable pin lengths, compliant contacts, and staggered or modular configurations that allow the same connector series to be used across multiple applications. Features such as alignment pegs, retention clips, and latching mechanisms help ensure that the connector fits securely on boards of varying thickness, preventing accidental disengagement and maintaining consistent electrical contact under operational stress.

Electrical Performance Considerations

Pitch and board thickness not only affect mechanical fit but also influence electrical performance. Larger pitch connectors can often carry higher currents due to the increased spacing between pins, reducing the risk of overheating or voltage drop. Proper alignment on the board ensures resistance and suitable current flow, which is especially important in power delivery applications. Connector selection based on both pitch and board thickness ensures that the system meets the required electrical specifications without compromising safety or efficiency.

Practical Applications and Flexibility

Different applications require connectors compatible with a wide range of pitches and board thicknesses. Industrial machinery, automotive electronics, and server systems may demand connectors that handle high currents on thicker PCBs, while consumer electronics often use compact designs with smaller pitch connectors on thinner boards. The versatility of Board to Board Power Connectors allows manufacturers to standardize parts across multiple platforms while ensuring performance and reliability.

Ensuring Proper Selection for Reliable Connections

Selecting the correct Board to Board Power Connector involves careful consideration of both pitch and PCB thickness. Proper alignment and mechanical engagement ensure stable electrical connections, while accommodating different board thicknesses prevents mechanical stress and potential damage. Understanding these parameters helps engineers and designers optimize performance, maintain reliability, and extend the operational lifespan of electronic systems. By matching connectors to the specific board spacing and thickness requirements, manufacturers can achieve both efficiency and safety in their designs.

English

English 中文简体

中文简体 Español

Español عربى

عربى