Practices for Robust Connections Ensuring Reliability in WTB Wire to Board Connectors

Understanding the Importance of Connection Reliability

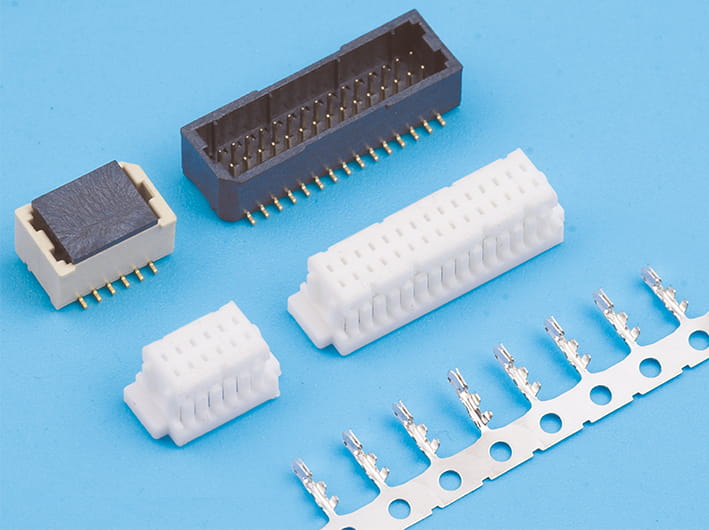

In modern electronic systems, a reliable electrical connection is essential for uninterrupted performance, especially in compact or mission-critical devices. The WTB Wire to Board Connector plays a vital role in establishing a stable link between individual wires and printed circuit boards. To ensure long-term dependability, several factors must be considered during selection, assembly, and operation. A failure in this connection—whether through intermittent contact, corrosion, or mechanical damage—can cause malfunction, data loss, or safety risks.

Choosing the Right Connector for the Application

Reliability begins with selecting a WTB Wire to Board Connector that matches the application’s electrical, mechanical, and environmental requirements. Considerations include current and voltage ratings, pitch size, pin count, and operating temperature range. For applications subject to high vibration or thermal cycling, connectors with locking mechanisms and high-retention terminals are good. If the application is exposed to moisture or dust, connectors with appropriate sealing features or IP-rated designs should be chosen.

Proper Crimping and Termination of Wires

One of the common causes of connection failure is poor wire termination. Using the correct crimping tools ensures a secure and electrically sound connection between the wire and terminal. Each wire gauge must be matched with its designated terminal size, and the crimp profile should be verified for proper compression. Cold welds, loose crimps, or frayed wires can increase resistance, cause signal loss, or result in complete disconnection over time. Many manufacturers recommend using automated or calibrated hand tools to maintain quality consistency.

Ensuring Correct Insertion and Mating

Proper mating of the wire housing with the PCB header is essential. Misaligned or partially inserted connectors can cause poor electrical contact and increase the risk of arcing or mechanical damage. Most reliable WTB Wire to Board Connectors incorporate polarization features or keyed designs to prevent incorrect mating. Additionally, visual or tactile feedback mechanisms, such as “click” locking tabs, help confirm that the connector is fully engaged. Avoiding repeated unmating and remating unless specified can also help preserve contact force.

Maintaining Contact Integrity Over Time

Contact design significantly impacts the connector’s ability to maintain low contact resistance throughout its life cycle. Features such as dual-beam or cantilever spring contacts provide consistent pressure on the mating surfaces and help absorb minor vibrations. Connectors with gold or tin plating are often used to enhance corrosion resistance and prevent fretting wear. Ensuring a clean environment during assembly—free from oils, dust, or metal particles—further improves long-term reliability.

Strain Relief and Cable Management

To protect the connector from mechanical stress, strain relief techniques are essential. These include integrated cable clamps, molded housings, or external cable tie-downs that prevent wires from pulling on the contact points. Excessive force on the wire-connector interface can gradually weaken the crimp, dislodge the housing, or damage the PCB solder joints. Additionally, proper cable routing, avoiding sharp bends or tight bundles, reduces tension and the chance of fatigue failures.

Periodic Inspection and Preventive Maintenance

In high-reliability applications, connectors should be part of a routine inspection schedule. Visual checks for corrosion, discoloration, or mechanical damage can help identify early signs of failure. For field-replaceable connectors, it is also advisable to use dielectric grease or protective covers when specified by the manufacturer to reduce environmental degradation.

Holistic Practices Drive Reliable Wire-to-Board Connectivity

Achieving a dependable electrical connection with a WTB Wire to Board Connector requires more than just proper selection. It involves disciplined practices in wire preparation, crimping, mating, mechanical support, and environmental protection. By understanding the key factors that influence connector performance and addressing them systematically, engineers can ensure consistent, long-term reliability in their electronic systems.

English

English 中文简体

中文简体 Español

Español عربى

عربى