High-Frequency Signal Transmission Performance and Challenges of FFC Ribbon Cable in Modern Electronics

Flexible Flat Cables are widely used in various electronic devices due to their thin profile, flexibility, and ease of installation. However, when it comes to transmitting high-frequency signals, the performance of FFC Ribbon Cable involves several technical considerations. This article explores how it behaves under high-frequency conditions, the challenges encountered, and the design strategies employed to optimize signal integrity.

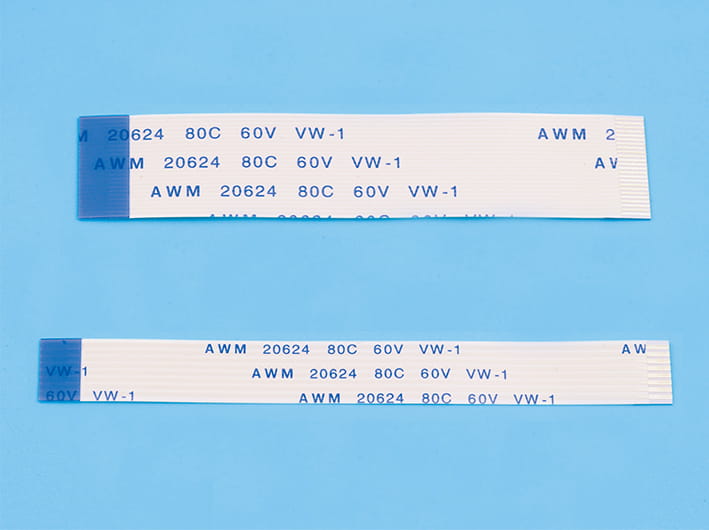

At its core, FFC Ribbon Cable consists of multiple flat conductors arranged in parallel, embedded within a thin insulating film. This construction offers space-saving advantages, but it also influences electrical characteristics such as impedance, capacitance, and crosstalk—all critical factors for high-frequency signal transmission.

One of the primary challenges for FFC Ribbon Cable in high-frequency applications is managing signal integrity. As frequency increases, issues like signal attenuation, reflection, and electromagnetic interference (EMI) become more pronounced. The relatively close spacing of conductors in it can cause increased capacitive coupling and crosstalk between adjacent lines, which can distort the signal and degrade performance.

Impedance control is another key factor in high-frequency signal transmission. Unlike coaxial cables or twisted pair cables, FFC Ribbon Cable typically lacks inherent shielding and precise impedance matching, which can result in signal reflections and loss. Designing it with controlled impedance requires careful selection of conductor width, spacing, and dielectric materials. The cable’s dielectric constant and thickness significantly affect its characteristic impedance, influencing how well it can carry high-frequency signals without distortion.

In practical terms, the skin effect at high frequencies causes current to concentrate near the surface of the conductors, effectively reducing the cross-sectional area available for conduction and increasing resistance. Since FFC Ribbon Cable conductors are thin and flat, skin effect can cause increased signal loss compared to round wire cables. This phenomenon must be accounted for in cable design and signal conditioning.

Thermal effects also play a role in high-frequency performance. As signal frequency and data rates increase, the heat generated by conductor resistance and dielectric losses can impact cable reliability. Efficient heat dissipation is more challenging with thin, flexible cables like FFC Ribbon Cable, necessitating materials with good thermal properties.

Despite these challenges, FFC Ribbon Cable can perform effectively in high-frequency applications with proper design and installation techniques. Using low-loss dielectric materials such as specialized polyimide or fluoropolymer films helps reduce signal attenuation. Increasing conductor width and optimizing spacing can reduce crosstalk and maintain controlled impedance. Additionally, incorporating shielding layers or grounding conductors can significantly improve electromagnetic compatibility.

Manufacturers often customize their constructions for specific high-frequency uses, such as display interfaces (e.g., LVDS, eDP), camera modules, and communication equipment. In these applications, the cable length is typically kept short to reduce signal degradation. Proper connector design and precise termination are equally important to maintain signal integrity from source to load.

Installation practices also influence performance. Avoiding sharp bends, maintaining bend radius, and securing the cable to prevent vibration can reduce mechanical stress that might otherwise affect electrical continuity and signal quality. Furthermore, routing FFC Ribbon Cable away from high-power or noisy components helps mitigate electromagnetic interference.

English

English 中文简体

中文简体 Español

Español عربى

عربى